Installation of Roundit EMI FMJ

5th Apr 2022

Roundit EMI FMJ has many applications and is notably used in the aeronautical, space and military industries. Assembled by experts at the Union of Concerned Scientists (UCS), the Satellite Database is a listing of the nearly 2000 operational satellites currently in orbit around Earth. With additional launches and satellites in orbit in 2019, this figure is expected to continue to grow.

Below is a short guide to the installation of Roundit EMI FMJ. For a more comprehensive installation guide on EMI FMJ and other products please visit our resources page.

Description

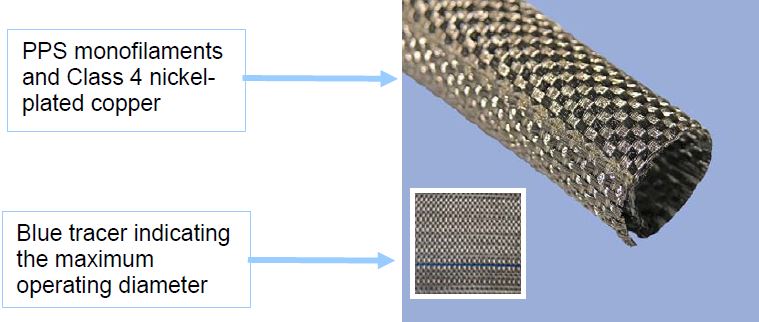

ROUNDIT® EMI FMJ (Full Metal Jacket) is a wrap-around sleeving designed for high-performance EMI shielding of wire and cable bundles. ROUNDIT EMI FMJ is manufactured from PPS monofilaments and nickel plated copper. It includes a blue tracer line indicating the maximum operating diameter.

Application

Roundit EMI FMJ can be used for:

- EMI protection and bundling for electrical harnesses in all aircraft zones

- Open solution for modification in the original harness

- Repair of EMI shielding

Installation

- The wire bundles must be prepared before installing Roundit EMI FMJ. To help with installation, some breakout bundles can be tied to hold the wires in place. This operation should be done minimally, using as little lacing tape or tape as possible since the complete harness with the sleeve will be tied after the installation of Roundit EMI FMJ.

- The two layers of Roundit EMI FMJ are cut with scissors. The textile fabric of the sleeve has an anti-fray system with a knot at the edge.

- The Roundit Tool can be used to facilitate the installation of Roundit EMI FMJ on bundles for sizes below 25mm while removal of the sleeve can be performed manually without tools.

- Roundit EMI FMJ on the bundle must be tight in order to avoid folds. To make it easier for multi-branch harnesses, it is better to start covering the smallest bundle and finish with the biggest. This makes it possible to cover the small size by a bigger size on the break-out.

- Roundit EMI FMJ must be twisted on all bundles. The twist shall be on average around 1 to 2 turns per linear meter (2 turns/yard) of the bundle. In order to ensure the good performance of the transfer impedance, it is important not to twist Roundit EMI FMJ too much. Do not exceed two twists per meter.

Connection and Fixation of the Sleeve

- Roundit EMI FMJ junction on connector back shell and break out accessories are made with Band-It. The sleeve on the bundle must be tied with cable ties or lacing tapes. The cable tie or lacing tape interval is 10 cm.

- A silicone Tape 67N (ABS 5334) can be added to finish the ends. It adds local waterproof protection (salt spray resistance) and prevents injuries.

For more information on branches, termination and repair visit our resources page.

Product Sizes

- Roundit EMI FMJ 5-8, 5623000508S / 5624000508S

- Roundit EMI FMJ 8-8, 5623000808S / 5624000808S

- Roundit EMI FMJ 13-8, 5623001308S / 5624001308S

- Roundit EMI FMJ 19-8, 5623001908S / 5624001908S

- Roundit EMI FMJ 25-8, 5623002508S / 5624002508S

- Roundit EMI FMJ 32-8, 5623003208S / 5624003208S

- Roundit EMI FMJ 38-8, 5623003808S / 5624003808S

If you're interested in Roundit EMI FMJ for your application Titan Electronics stocks a variety of sizes as well as the Roundit Tool for installation.